Power

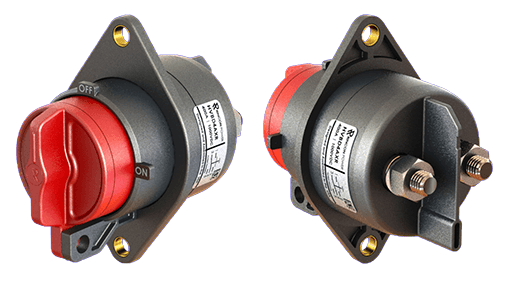

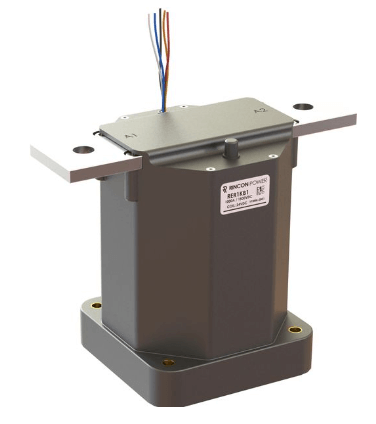

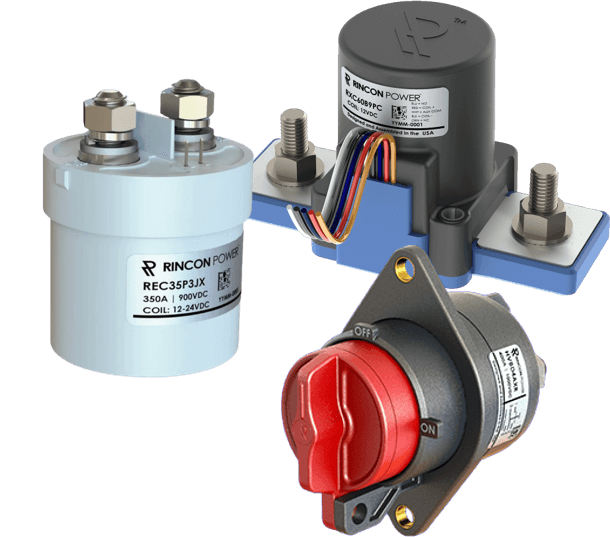

contactors

What is a power contactor ?

Power contactors are essential components in the electrification of mobile machinery and, more generally, in electro-mechanical power systems. They are used for two purposes :

- Connection of the precharge circuit : In electrical systems, many capacitors become charged when the machine is switched on or when the power supply to certain blocks in the overall system is initialised. These discharged capacitors will create high current demands which will require a specific circuit and management: a precharge circuit. During this precharging stage, the contactor must be sized so that the peak currents and their duration are known.

- Connecting and disconnecting machine loads : Energy-consuming loads can be of 3 types: resistive, capacitive or inductive. Depending on this first parameter, as well as their voltages, consumption current and use, the efa France design office will choose the most suitable solutions.

How to select a contactor?

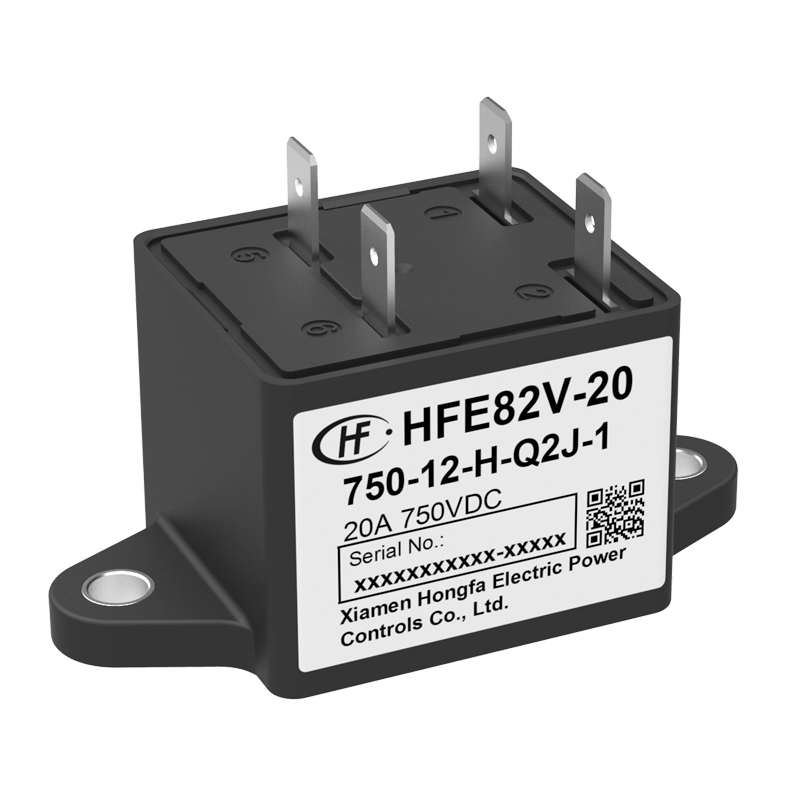

1 // The cut-off current

The breaking current of a power contactor is the maximum value of the electrical current it can safely interrupt. This parameter is essential for choosing a contactor suitable for the electrical load you plan to control, ensuring that it can handle the current safely without risk of overheating or electrical arcing. This current is specified as a peak or rated value. To optimise product sizing, you need to know the current curves.

2 // Switching voltage

The breaking voltage of a power contactor is the maximum voltage it can effectively interrupt. It is crucial to select a contactor with an appropriate cut-off voltage for your application, as too high a voltage could cause dangerous arcing or damage the contactor.

3 // Control voltage

The coil control voltage is the voltage required to activate the contactor and close or open the main contacts. It must be compatible with the control source, such as a manual override or automatic control circuit. It is important to select the correct coil voltage to ensure correct operation of the contactor. Above the voltage value, some contactors are PWM controlled while others are DC voltage controlled.

4 // Auxiliary outputs

The auxiliary outputs of a power contactor are additional contacts used for signalling or control functions. These outputs are used to control other devices or to provide information on the status of the contactor. They are useful for monitoring and diagnosing electrical circuits.

5 // Mechanical fastening

The mechanical fixing of a power contactor refers to the way in which it is mounted or secured in the electrical installation. It can vary depending on the model of contactor, with options such as DIN rails, fixing screws or other mechanisms. The choice of mechanical fixing depends on the location and configuration of the electrical installation where the contactor will be installed.

6 // Performance derating as a function of the number of cycles

After a large number of cycles, the contactor’s performance will decrease. The permissible currents and voltages will deteriorate. This is due to the ageing of the metal parts used for electrical contact. Over time, line resistances will become stronger and may lead to overheating.