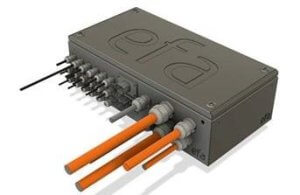

In the world of electrification, safety is an absolute priority.

Respecting insulation distances is therefore a challenge we have to meet to protect both operators and equipment.

Challenges & constraints :

⚠️ Space constraints: Within a compact PDU, finding enough space to respect insulation distances can be difficult. Many components need to be integrated into a small space.

⚠️ High voltages: PDUs for high-voltage applications require greater isolation distances, which can pose additional design challenges. Voltage spikes also impact on these values.

⚠️ Standards and regulations: Electrical safety standards and regulations impose strict requirements on insulation distances. IEC 60664-1:2020 is an example of the normative constraints applied in efa France’s designs.

Our innovative solutions :

✅ Optimised use of PCBs: We use advanced design techniques to optimise the layout of components on printed circuit boards (PCBs) according to the potentials at the terminals of critical components. The compactness of PDUs is now a key criterion for mobile machines. Our design office teams are committed to reducing the distances between components without compromising safety.

✅ High-quality insulating materials: We carefully select high-quality insulating materials for PDU components, ensuring reliable insulation while minimising the space required. In addition, all designs produced by our teams undergo extensive testing to ensure that our solutions are reliable right from the prototype stage.

✅ Modelling and simulation: We use modelling and simulation tools to assess and optimise the insulation distances of our PDUs. This ensures optimum safety and compliance with standards while optimising space.

To find out more about our PDU solutions and electrification capabilities, please contact us or visit our website.