On-site integration

efa France is taking a new strategic step in its industrial development: integrating the design and manufacture of pressfit electronic boards in-house. This expertise paves the way for high-performance applications, while strengthening efa’s technological independence in the service of its customers.

Pressfit, a solderless technology

Pressfit enables component pins to be inserted into PCBs without soldering, using controlled mechanical pressure. The result is excellent electrical conduction, particularly for high currents, and enhanced reliability in demanding environments.

To make this breakthrough a reality, efa has joined forces with the specialist MTConnectivity, a European reference in the field of industrial connectors.

“We are very pleased about our partnership with efa! Their dynamism, innovative spirit and clear focus on quality and customer benefits have impressed us from the very beginning. We are convinced that this collaboration holds great potential – for exciting projects, new impetus and sustainable success on both sides.”

The advantages of this technology

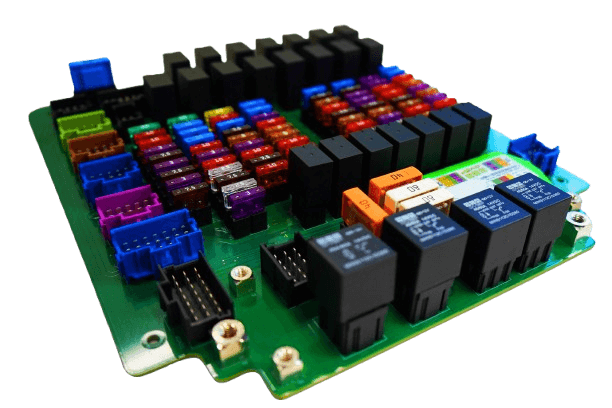

Thanks to this technology, efa can now design electronic boards that combine performance, compactness and robustness:

✅ More power: Pressfit increases current capacity, while improving production costs

✅ Total control: In-house production for greater responsiveness and customisation

✅ Multi-physics optimisation: efa’s Electricity, Energy and Mechanics teams model your boards to ensure optimum thermal and electrical performance

✅ Space savings: Better conduction in the PCB means smaller systems, especially PDUs (Power Distribution Units)

Towards new industrial prospects

By mastering this advanced technology, efa is positioning itself as a key player in industrial power connectors. It is also a demonstration of its determination to innovate, to produce locally, and to offer its customers solutions that are reliable, compact and high-performance.